Do you work with sharp objects such as wire, iron cladding or blades? Then choosing the right cut-resistant gloves is vital to your hand safety. Whether you're on a construction site, in forestry or packing in a warehouse, looking after your hands should be a number one priority. To help you keep you and your team safe, we've pulled together a quick guide on Glove Cut Resistance Ratings and how to pick the glove that's right for your workplace.

Understand EN388:2016 Labelling

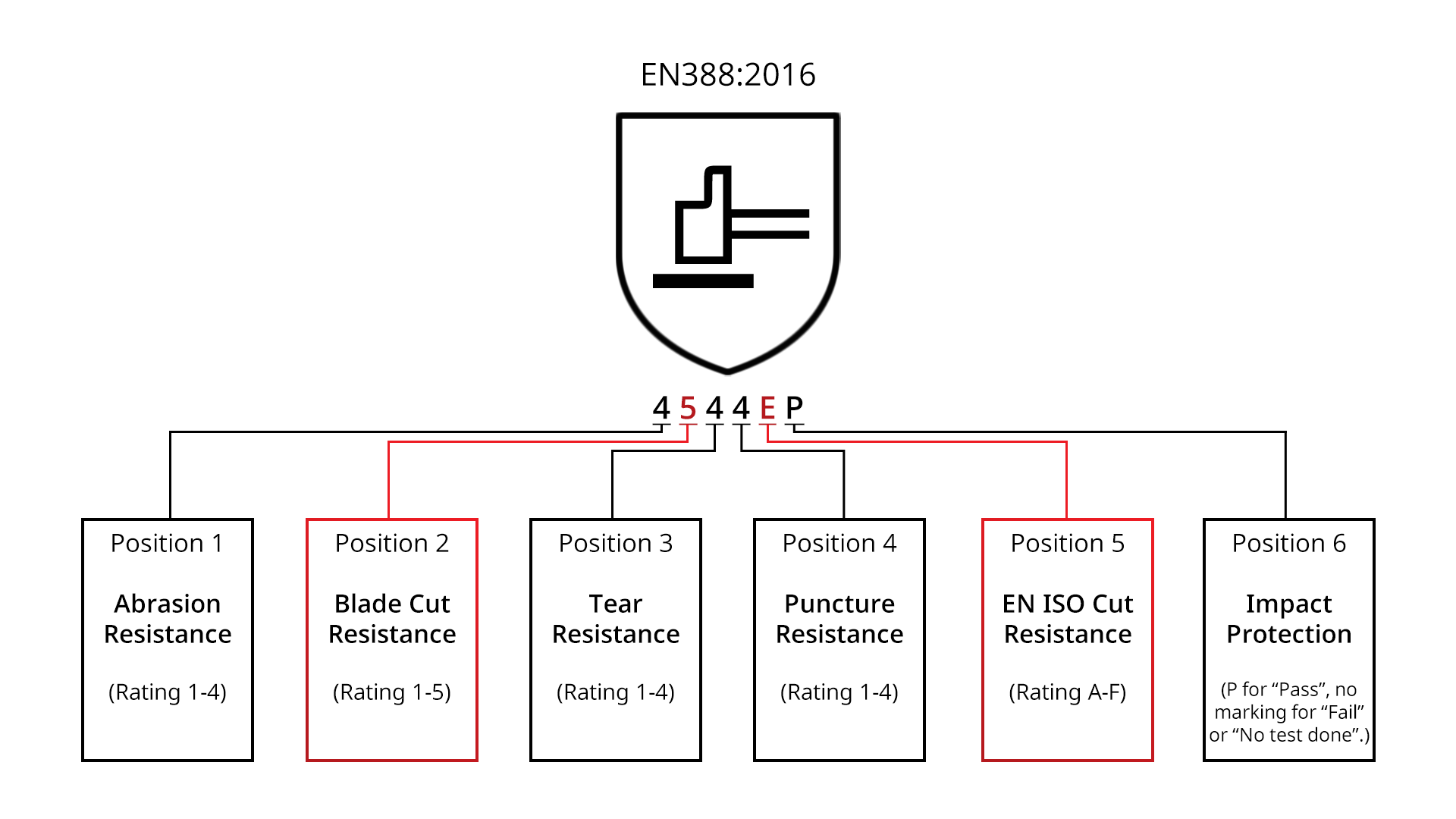

The first thing to know is how the EN388:2016 rating system works. You can see what your glove's rating is by a symbol which looks like the one below (it's often printed directly onto your glove).

The numbers and letters below the symbol will change according to the safety rating of the glove. The number and letter you should pay special attention to for cut resistance are Position 2 and Position 5:

Position 2 - Blade Cut Resistance

This position represents how the glove performed in a test called the Coup Test. This test is done by passing a blade over the glove material until it cuts through. If the material dulls the blade during the test, the EN ISO Cut Reststance Test (Position 5) is performed.

Position 5 - EN ISO Cut Resistance

This position represents how the glove performed in a test called the EN ISO Cut Resistance Test. In this test, a blade is passed over the material, but with increasing force until it breaks through.

The higher the number for Position 2 (Blade Cut Resistance) and the closer to F the letters are on Position 5 (EN ISO Cut Resistance) the more protection against cuts your glove provides. However, there are other factors to consider before you simply go for a glove with "high" cut resistance.

Factor in your environment and work style

Is your team working with wires or building materials? Or are they handling waste, metal sheets or even machining and grinding? All of these activities come varying with cut risk, but they also require different levels of dexterity.

This is where Position 5 (EN ISO Cut Resistance) is important to take into consideration.

Ansell have broken down some common industrial tasks for each rating (see table below). Please use these as a general guide. No glove provides complete protection against cuts, abrasions and chemicals. Also, your work environment will have a big impact on how effective your safety gear is. Make sure you test yours in context of how you and your team work.

IN ESO Cut Resistance Rating: Common tasks associated with each rating

EN ISO Cut Level Resistance is measured in Newtons and ranges from level A to level F. The more weight is required to cut through the glove, the higher the rating.

This guide has been sourced from Ansell's Safety Briefing Cut Level Guide. The information provided is intended to be used as a general guide on the appropriate level of protection for some common industrial tasks.*

| Cut Level Rating |

Resistance (Newtons) |

Protection Level |

Typical Tasks |

| A |

2 |

Minimal to low |

- Screwing and unscrewing

- Raw materials reception

- Grinding and fettling

- Shipping and receiving

- Warehouse work

- Stamping operations

- Inspection and packing of small components

- General handling

|

| B |

5 |

Low |

- Wire assembly and fastening

- Metal part and component assembly

- Plastics injection and moulding

- Light metal presses

- Whitegoods assembly

- Glass repair

- Building materials handling

|

| C |

10 |

Low to moderate |

- Body shop work (excluding welding)

- Glass or metal sheet handling

- Stamping

- Hardware assembly

- Raw materials handling

- Glass manufacturing

|

| D |

15 |

Moderate to high |

- Metal parts and components assembly

- Automated welding and feeding

- Metal finish inspection

- Machine tool operation

- Sheet metals and metalwork

|

| E |

22 |

High |

- Waste handling (recycling and sorting glass, cans or other metal pieces)

- Handling heavy loads and metal edges

- Handling glass sheets or sharp-edged objects

- Metal sheet handling

- Cutting of dry, painted or galvanised metal pieces

|

| F |

30 |

Extreme |

- Heavy final assembly

- Machining and grinding

- Maintenance work

- Materials handling

- Metal press work

- Primary assembly

- Stamping

|

*This information is general in nature and should not be taken as professional advice. This guide has been prepared to allow viewers to understand the concepts of cut resistance. No glove provides complete protection against cuts, abrasions or chemicals. Glove users should undertake their own testing within their own work environment to ensure that the gloves are suitable for the intended task. No reliance may be made on this guide as evidence of the efficacy or fit for purpose of these gloves.

Other things to consider when purchasing gloves

-

Comfort

One of the most challenging aspects of Health and Safety is making sure your team actually adhere to your PPE policy by wearing the gear provided. By ensuring your gloves are not only protective, but comfortable to wear as well, you'll increase the likelihood of continuous wear. Look for lightweight material gloves with a suitable lining.

-

Grip

Selecting a glove with suitable grip is very important. Failing to do so can lead to higher injury rates. Heavy objects with sharp edges can slip when being handled, resulting in a slicing motion through the glove. This is especially important when handling wet or oil-covered objects.

Insufficient grip can also contribute to other conditions, such as muscle strain, stress and fatigue.

-

Glove coating

Gloves are often coated in extra materials to improve their protection and performance. The type of coating you choose will depend on the type of work you do. Some are more suited to working with chemicals or oil/grease (such as Nitrile rubber, PVC and Neoprene). Others are better for wet conditions or where you need more dexterity (such as Latex or Polyutherane). Before you buy, check with a specialist and test the gloves in your work environment.

-

Dexterity and size

No matter what the work is, comfort and dexterity should always be considered. If your team can't work with the glove, or it's uncomfortable, then there is a high likelihood they won't wear them at all. Also, make sure you're catering to all hand sizes. Gloves that are too big or too small don't offer adequate protection (if they're even worn at all).

-

Material

Depending on your environment and the needs of your team, the material your gloves are made of could have an impact on your decision too. You may need to consider latex or silicone-free gloves to accommodate allergies. Or anti-static options for teams who are working with sensitive electrical equipment.

-

Designed for duty

You will also want to consider suitable length, fit and cuff style depending on the tasks being done. When purchasing your gloves, look for suppliers that make industry-specific recommendations.

Take the level of duty into consideration as well. Cut resistant gloves can be divided into the following three categories:

Light duty – Not designed for heavy work, these gloves should only be used for light work

Medium duty – These gloves are designed to withstand moderate loads, use or stress

Heavy duty – These are designed to withstand hard use or wear

There are a lot of factors to take into consideration when fitting a team out with safety gear. Talk to one of our Safety Specialists to find a solution that's right for you.